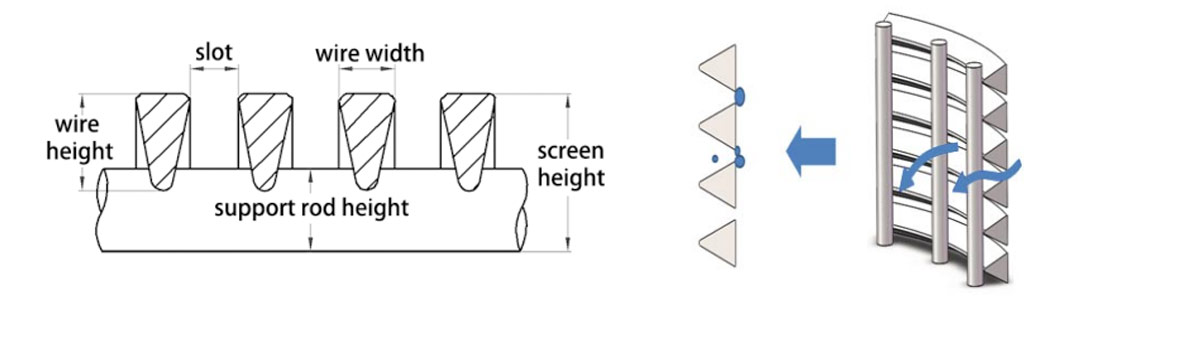

Water well screen also called Continuous Slot well screen are made from two elements the V-shaped wedge wire is helically wound around an array of internal longitudinal support rods. Each intersection of wire and rods is automatically resistance welded, creating a very strong cage-like cylinder with one continuous slot spiralling along its full length. The gap between the wires, also called slot or aperture, is manufactured to customer specification, allows water to flow from the surrounding aquifer into the screen, The slots can be very narrow to keep out fine sand grains, which could otherwise damage your pump through abrasion.

DESCRIPTION

KEY DESIGN FEATURES OF WATER WELL SCREEN

NON PLUGGING SLOTS

>V-shaped wire creating, two point particle contact preventing plugging

> Inwardly opening slots (in-flow) preventing sand particles from remaining lodged in screen

> The V-shaped wire enhances well efficiency, ensures consistent pumping and long well life.

LARGE OPEN AREA

> The continuous slot wedge wire offers higher open area than any other type of screens used for water well applications, such as slotted pipe, punched pipe, louver screens

> Wedge wires for each application are selected to maximize open area, resulting in the lowest possible cost for water extraction.

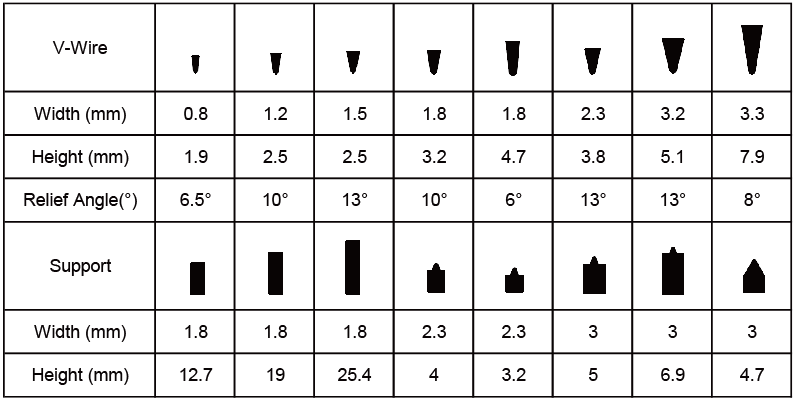

SPECIFICATIONS OF WATER WELL SCREEN

Slot: from 0.1mm, tolerances: ± 0.05mm.

Maximum length: 6000 mm.

Diameter: from 25 mm to 1200 mm.

Material: Low Carbon, Low Carbon Galvanized steel (LCG), Stainless Steel ( 304, 304L, 316, 316L, etc.).

End Connection: Plain beveled ends for butt welding or threaded.

APPLICATIONS OF WATER WELL SCREEN

High strength continuous slot stainless steel water well screen are widely

used in water well for efficient water filtration and sand control. It can

also be used in the oil and gas wells.

Copyright © Anping TianHui Wire Mesh Products Co., Ltd. All Rights Reserved | Sitemap |

Technical Support: